TL;DR? Skip to the review after the line break, or the board form for the full technical writeup.

Let’s be perfectly clear here: ipXchange understands that there is a difference between electronics hobbyists, makers, and professional design engineers working either independently or at OEMs. For many, Arduino’s boards may have been the gateway to their embedded or electronics journey, and while ipXchange may be of interest to some higher-level hobbyists, our goal is to serve professional design engineers. In some cases, however, this may include maker-level engineers that are working on multiple-unit commercial projects, so perhaps the line is not as defined as one might think…

With ipXchange having been invited to cover Maker Faire Rome next month (October 20th – 22nd), we think it’s time to take a step back and see who our audience/membership truly are. Would maker content be relevant to them in their work, or would it simply be something they might find interesting, because ‘making’ is something separate from engineering; it’s something inside that drives us to learn, create, and celebrate what it means to build something yourself, right?

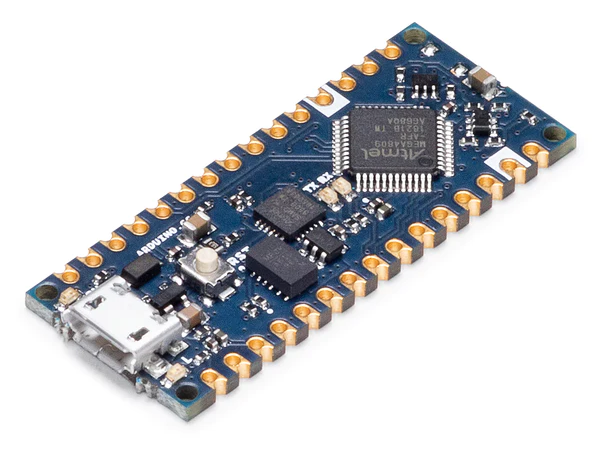

For those who follow our main content writer Eamon on LinkedIn, you may have seen that he has been playing with Arduino’s Nano Every board, the smallest (45 x 18 mm), simplest (8-bit Atmel MCU without connectivity), and lowest cost (approx. £11) platform that this leader of the maker movement has to offer. Eamon is not a professional design engineer, but he is a maker of sorts. He has made and modified guitars and other electric/electronic musical instruments since he was 15 years old. But this does not mean he has never thought of selling his ideas, so what does he think of the Arduino Nano Every? Here’s the honest truth.

Arduino’s Nano Every: What Eamon learnt over a few weekends with this board

Eamon here, and above, but writing in the third person as usual. If you simply want a full technical rundown of the Nano Every, head to the board page, which provides a comparison with the original Arduino Nano and highlights some of the key features of the platform. But here, I’ll recount my experience of the Nano Every and where I think it fits in the world of commercial design engineering; Arduino are definitely making a go of that market with their PRO range, but with so many development platforms based on the UNO and other ‘maker’ form factors, Arduino’s Nano and MKR lines surely have a place in the professional realm.

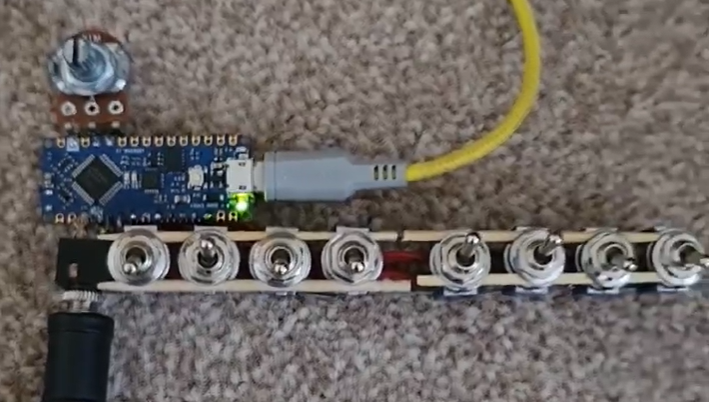

To begin, the reason why I chose the Nano Every, with its 45 x 18 mm form factor, was the 5-V logic and the wide supply range (7-21 V) that would suit the standards of my (musical) synthesisers and the 9-V supplies they run off; this is contrary to the Raspberry Pi Pico I own, which features 3.3-V logic and can be powered using 1.8-5.5 V. I also knew that at 15 mA per I/O pin, I would be able to power whatever I made off batteries, namely a PP3 9-Volt battery, and after finding that a pack of 15 SPDT toggle switches was actually cheaper than buying a few for a battery ON/OFF, I decided that making an 8-step sequencer would be the logical course of action, or at least that I would try to do so; I’ll cover this in a personal post on my LinkedIn when I finish the project.

I am not an embedded electronics engineer. If anything, I have a basic understanding of analogue filtering, signal processing, and amplification. To be perfectly candid, I was terrified of ‘learning to code’, but some MicroPython on the Pi Pico showed me that embedded coding is fun to get the hang of.

With the Nano Every, I wanted to take what I had learnt and apply it within Arduino IDE in the C++ language, something I was also nervous to do. You see, if you’re an electronics engineer but not an embedded engineer, I’m not sure coding seems to make sense until you try it out. It is a different language.

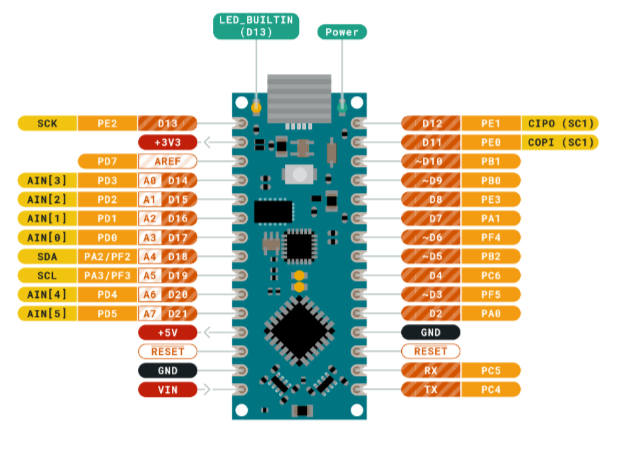

Looking at the Nano Every board and seeing there were 30 pins with a good mix of digital I/Os (14 dedicated), analogue inputs (8), PWM outputs (5) and standard interfaces for digital sensors or otherwise (I2C/UART/SPI), I thought it would be a great playground to try adding a layer of embedded logic to a project. The fact that the Nano Every has voltage rail pins at +5 V and +3.3 V meant that I knew I could power what I wanted from the board with whatever peripherals I might add as the project progressed, until I ran out of pins.

So far, I’ve been able to easily use the analogue inputs and digital I/Os to get my sequencer design to do pretty much what I want it to first time every time. Arduino’s IDE, and various online resources, provides so many easy-to-use examples that made this a fun project that could easily be turned into a limited-run commercial project if the idea wasn’t on the market already. But there are plenty of projects that should be on the market that aren’t, and I’m sure the Nano Every could be used to kickstart a few limited runs, whether they are robotic, musical, or wearable in nature.

I hear many of you thinking: “But the Nano Every is a glorified eval board for an 8-bit Atmel MCU that costs nothing. You’re wasting GPIOs and money putting this in a commercial design.” For well-versed embedded engineers, that very well might be the case, and if so, this board isn’t for you and your commercial project, but picture this:

You’re an engineer that has never touched an MCU. You don’t know how to program them, and you’re part of a small team that isn’t going to hire someone who does because you are the absolute best at analogue design for some boutique application. That said, one of you has had an idea about implementing some digital control functionality to make an incremental improvement to your product. You’re charging £1000 a piece for the privilege of owning your latest device that costs a fraction of that to make, and you’re only making 50 of them. Well then, maybe squeezing in a Nano Every is for you. It’s just a little microcontroller board. No wireless connectivity, no sensors, no extra fuss. Just 5-V control that could be easily integrated to add a little extra to your product.

And that’s where I think the Nano Every can help professional design engineers, and why I think easy-to-use MCU boards are something worth a look for anyone looking to bring their designs to life, fast.

Check out ipXchange’s full technical writeup by following the link to the board form below. We hope you’ve enjoyed this introduction to a little more hands-on maker-style content in the wake of what’s to come later this month.

Keep designing!

This is the current status of Eamon’s Arduino Nano Every project. Follow him on LinkedIn for more weekend tinkering.

(Product images sourced from Arduino)