It’s getting hot at PCIM 2025—and not just because of the foot traffic. At the YAGEO booth, we found Nanomat-based power inductors handling 120 amps with ease, all while running significantly cooler than their traditional ferrite or metal composite counterparts.

What’s a Nanomaterial Inductor?

YAGEO’s Nanomat inductors use a new magnetic core material made of ultra-fine particles. This nanomaterial offers higher permeability, enabling smaller core sizes without sacrificing performance. According to YAGEO, these inductors deliver higher current ratings and better temperature stability, all in a smaller form factor.

In short: more power, less heat, and a lot less board space.

Cooler Boards, Better Efficiency

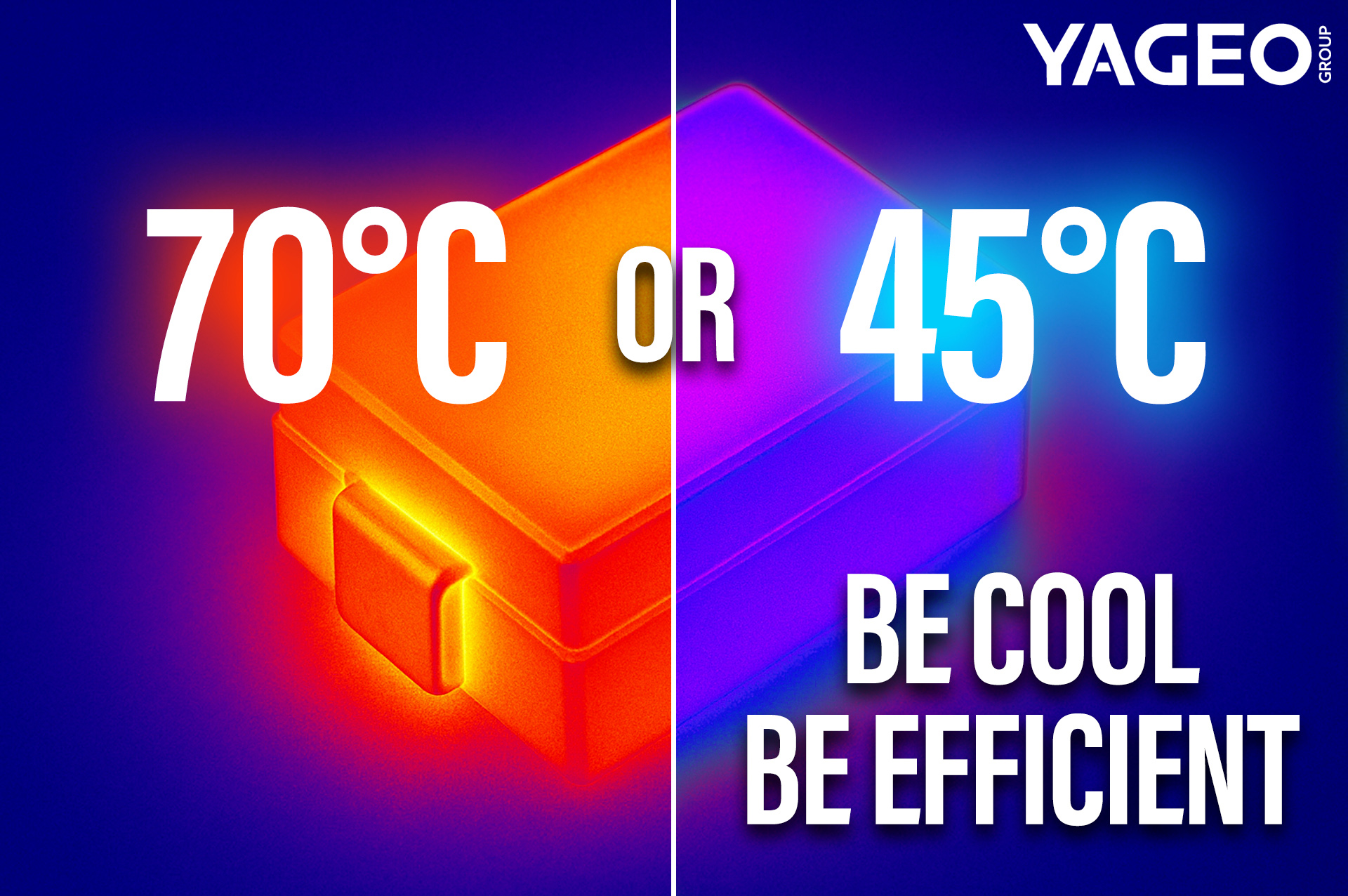

The demo spoke for itself. Side-by-side, a traditional inductor was running at around 70°C, while the Nanomat inductor sat comfortably at 45°C under the same load. That’s a clear indicator of lower core and copper losses, which translates to improved efficiency and longer component life—key considerations for power-dense systems like AI servers and GPU arrays.

The soft saturation characteristics of the Nanomat material also mean more predictable performance across temperature swings, unlike ferrite cores which tend to shift at high temps.

Seamless Integration for Design Engineers

Concerned about integration? Don’t be. The Nanomat series shares footprints with existing inductor types, so you won’t need to redesign your board to test or deploy it. The transition is practically frictionless, offering all the performance benefits with none of the layout headaches.

Whether you’re designing high-efficiency server hardware, advanced motor drivers, or compact power modules, these inductors offer a drop-in path to thermal and size savings.

Final Word

If you’re working in power-dense, thermally constrained environments—or just want to upgrade from bulky, less efficient inductors—YAGEO’s Nanomat power inductors are worth a close look. Higher current, lower heat, and compact footprints? That’s a compelling upgrade path for any modern power design.

Comments are closed.

Comments

No comments yet