Products

Applications

Solutions

Register your interest

In the onsemi iToF

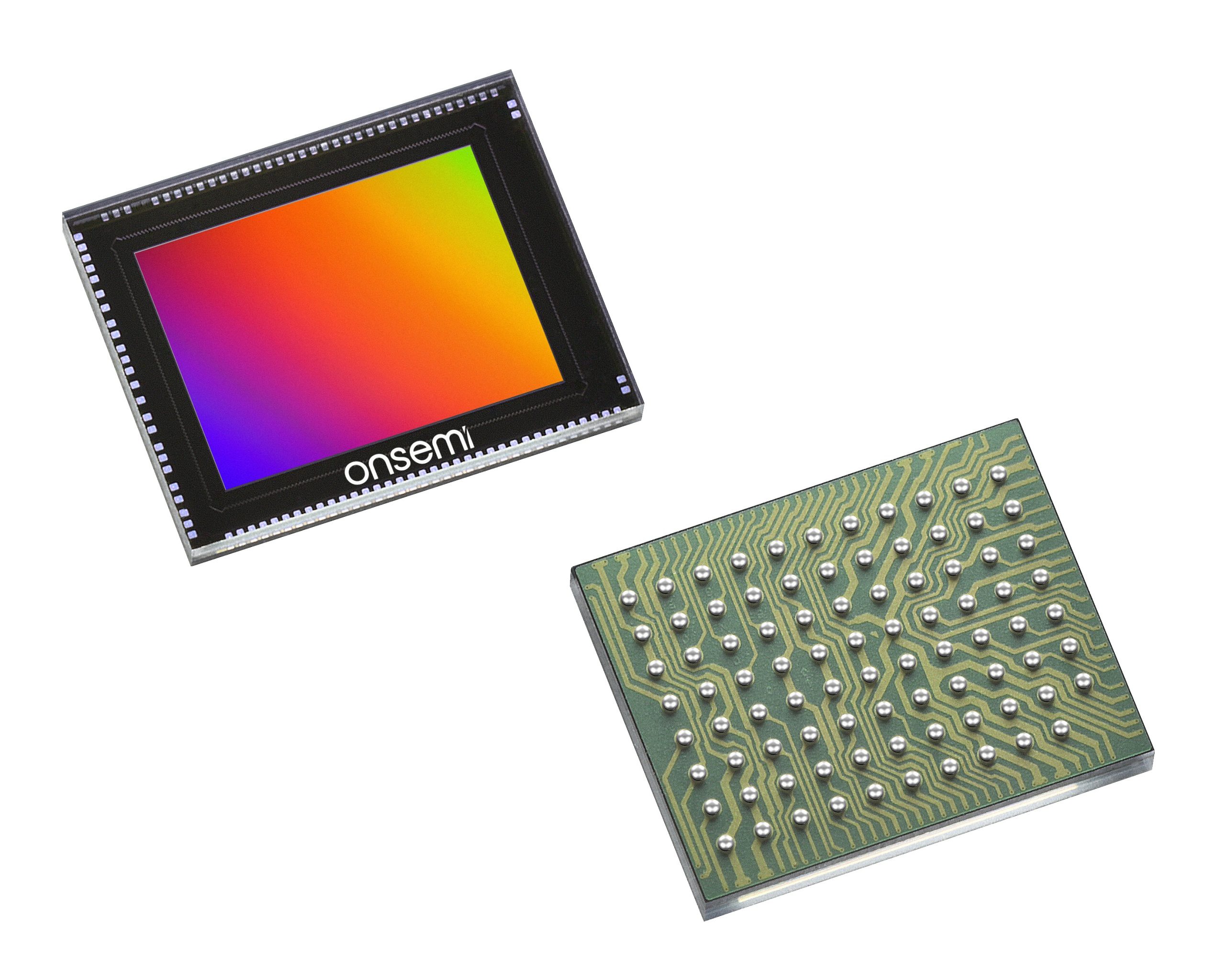

The onsemi iToF sensor platform enables real-time depth mapping for industrial and logistics applications, delivering 3D information without interrupting operations. Unlike legacy systems that require stopped conveyor belts or dual-camera stereo setups, onsemi’s indirect time-of-flight technology integrates depth calculation directly on-chip—ideal for tracking items in motion.

Using a global shutter image sensor with embedded depth processing, the onsemi iToF system captures both monochrome 2D images and pixel-accurate 3D depth maps. Engineers benefit from precise height and shape data, all processed in-sensor, which simplifies system design and offloads downstream compute. This makes it perfect for factory automation, parcel scanning, and smart robotics.

The onsemi iToF sensor is supported by a modular evaluation platform and proven ecosystem of optics and laser components. Engineers can start development using a reference design, adopt a plug-and-play module, or integrate the sensor directly into a custom camera. Integration is further simplified with partnerships from companies like IDS Imaging, who provide pre-calibrated finished cameras based on onsemi’s technology.

With conventional iToF systems, engineers often sacrifice speed for accuracy. But with onsemi iToF, asset tracking becomes seamless—even on high-speed lines. The sensor captures consistent data even when packages, bottles, or parts move rapidly across a production surface, thanks to high frame rates and built-in correction for motion artifacts.

Design engineers also benefit from onsemi’s robust application support. From development guides to reference optics and calibration suggestions, the ecosystem allows quick deployment across a variety of platforms. Whether you’re working on warehouse automation, vision-guided robotics, or inline quality inspection, onsemi iToF delivers both performance and integration simplicity.

Register your interest

In the onsemi iToF