Eamon here: As a former quantum computing physicist, I am always up for anything related to magnetics, and Paragraf’s graphene Hall effect sensors inevitably caught my eye. The sensor itself can be used for position, rotation, torque, and current sensing, and due to the high-purity graphene technology, they exhibit high resilience to mechanical stress, high sensitivity with reduced shielding requirements, very low power requirements, and immunity to in-plane stray fields – graphene is 2D.

The advantage that Paragraf’s graphene technology has over conventional silicon alternatives is its much higher accuracy, low-power operations, rugged performance, faster and more dynamic response, and a greater temperature operating range (1.8-353 K), making it suitable for cryogenic applications.

While there are obviously many places where a Hall effect sensor might be used, an intriguing application put forward by Paragraf is the use of their sensors to help design better electric vehicle batteries. This is done by placing sensors around a cell’s electrodes to sense the absolute current and the changes in current flow. This data can be used to examine how the cell’s internal resistance changes during operation, i.e. charging and discharging, and across its lifetime.

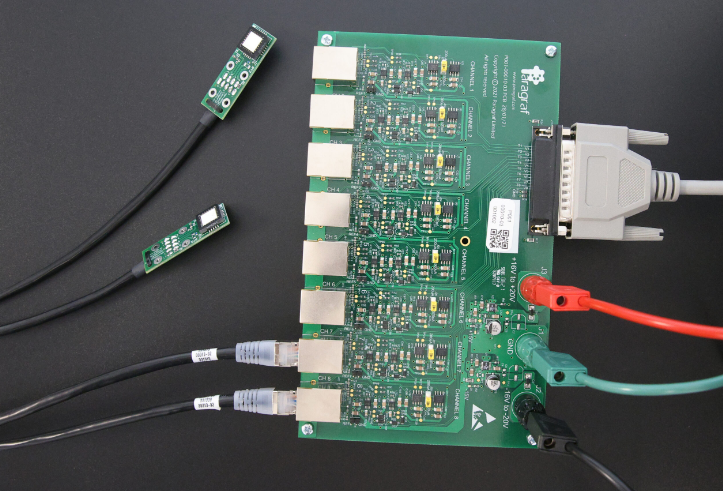

To this end, Paragraf created a development board which enables simultaneous measurements to be taken from up to 8 of their Hall effect sensors; the board would be integrated with existing data acquisition systems on the engineer’s end. For connection to this board, each sensor comes attached to a probe with its own temperature sensor and a 1.5 m serial interface cable, but these are not directly included with the package. While it was designed for the battery monitoring mentioned above, such a platform allows for many other magnetic testing opportunities, including projects that are not on Paragraf’s radar.

Keep designing!

(All images sourced from Paragraf)