Soluboard: designing a dissolvable PCB to rethink e-waste separation

By Sandro Mark

Electronic recycling is great at going after the obvious value, copper, gold, silver and other recoverable metals. The awkward bit is what the industry is forced to do with the PCB substrate itself. Traditional FR-4 is a glass-fibre and epoxy composite that is tough, stable, and cheap, but it is also a pain to recycle. Once a board is shredded, separated, or incinerated, that substrate typically becomes a low-value residue stream. It is often landfilled or downcycled at best.

Jiva Material’s Soluboard takes a different approach: change the material that causes the problem. It uses plant-derived fibres with a non-toxic, water-soluble polymer so the board can delaminate when exposed to hot water. The idea is simple, separate the waste streams early so metals and components can be recovered more cleanly, while the organic fibre element can be handled in a more sustainable way.

A practical test: design, build, assemble, then dissolve

To understand whether a new substrate is “real” for engineers, it has to survive the normal workflow. That is why we built a straightforward test design, an LED ring chaser that is quick to lay out and easy to validate on the bench. The goal was not to build a complex product, it was to prove the substrate can move through the same steps your boards do.

The design was intentionally kept simple, but the key point is that Soluboard is meant to be treated like a PCB laminate, not a science experiment. The most obvious manufacturing consideration is temperature, because the dissolution concept is tied to a polymer binder. In practice, that drives sensible choices in assembly profiles and materials, rather than forcing a total re-think of electronics manufacturing.

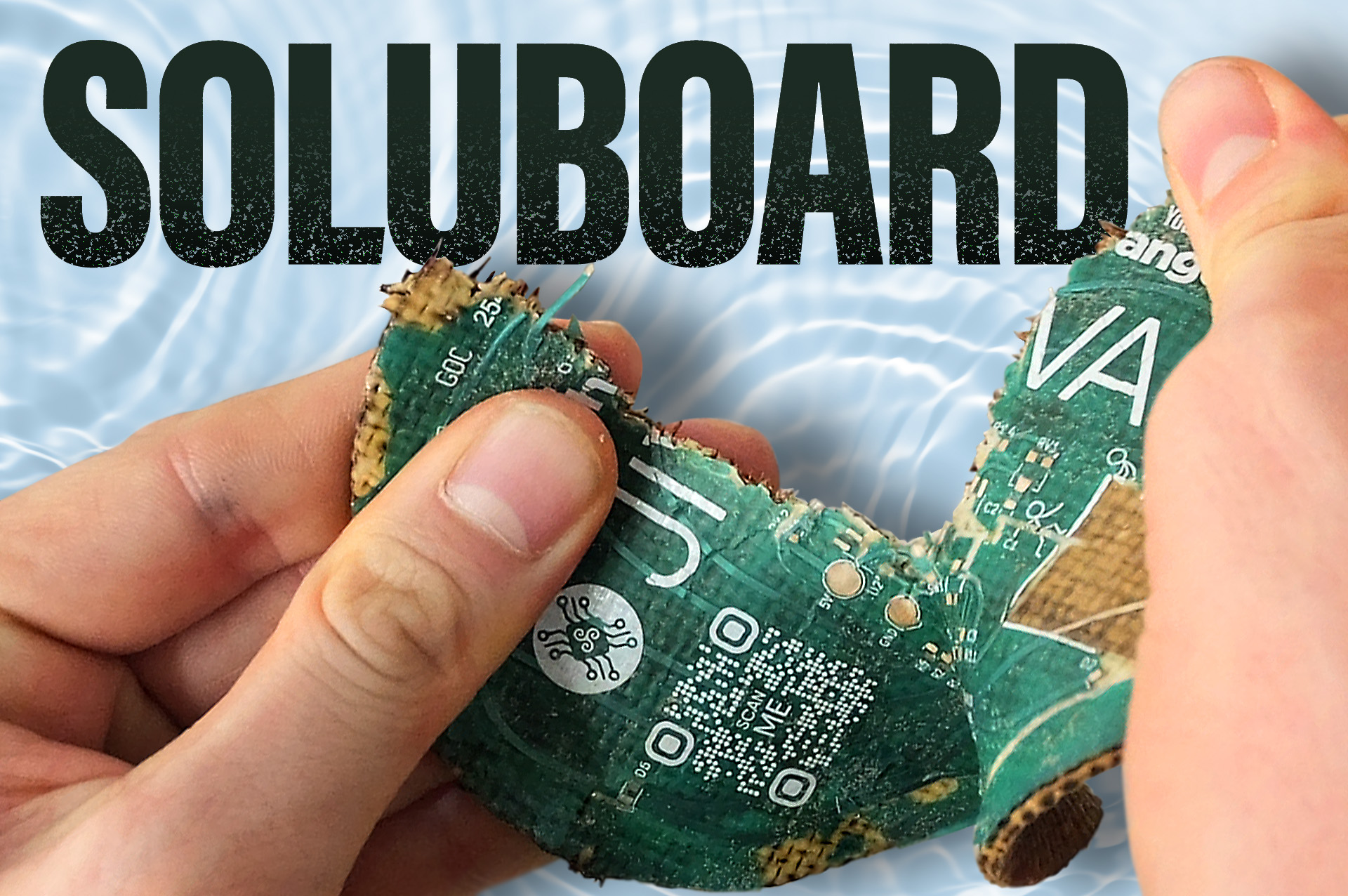

What happens when you dissolve a PCB

When a Soluboard-based PCB is immersed in hot water, the board delaminates, allowing separation between the substrate and the electronics. That separation is the whole game. If you can remove components and copper-bearing layers without aggressive mechanical processing, you can reduce contamination of recovery streams and avoid turning the substrate into an unrecyclable mixed waste.

This is not just a theory. Infineon has publicly discussed working with Jiva Materials on recyclable PCBs using Soluboard, describing a non-toxic polymer that dissolves in hot water and enables recovery of electronic components.

Why this matters: embodied carbon and end-of-life reality

Even before end-of-life, substrate choice affects footprint. Multiple sources report that Soluboard can deliver up to 67% reduction in embodied carbon compared to conventional FR-4, depending on the specific construction and use case.

But the bigger issue is what engineers rarely get to influence: what happens after the product’s useful life. If a substrate can be engineered to support easier separation, it can change the economics of recovery. It becomes more realistic to recover components, keep metals cleaner, and reduce the amount of composite waste that has nowhere good to go.

The engineer’s takeaway

If you design electronics, you are already making decisions that shape recyclability, even if recycling is not on the spec sheet. Soluboard is interesting because it targets the part of a PCB that normally blocks circularity: the substrate. It aims to keep the PCB workflow familiar while improving what happens at the end of the product lifecycle, especially around material separation and component recovery.

If you want more content like this, explore our site hubs for electronics manufacturing, materials innovation, and sustainable hardware design.

If you have a design that could make use of Soluboard, fill in this form for the chance to have your first prototypes sponsored by Jiva: https://form.jotform.com/260214030083339

Find more about Jiva Materials here: https://www.jivamaterials.com/

Comments are closed.

Comments

No comments yet