Enovix is a disruptive company that makes silicon-anode lithium-ion batteries with an integrated safety system that prevents catastrophic cell discharge in the event of damage. Their products come in a few sizes designed for wearables and hand-held devices, and I believe Enovix’s innovations provide a great reimagining of rechargeable battery technology.

The first innovation is the use of silicon anodes, rather than the more widely used graphite anodes of Li-ion batteries. Though there are a number of significant technical problems with silicon anodes, namely first charge expansion, first charge efficiency, cycle swelling, and cycle life, silicon anode technology can theoretically hold more than twice the capacity per volume of the graphite anode technology used in nearly all Li-ion batteries at the time of this writing (1800 mAh/cm3 vs. 800 mAh/cm3). Enovix’s battery design addresses these problems using a novel cell structure, limiting swelling to as little as <2% cell thickness after 500 cycles, swelling being one of the biggest issues with silicon anode technology. The details of these innovations are discussed on the Enovix website’s home page, which I should warn is a tad trippy, but please do not let it stop you from checking out the technology, particularly what I regard as the main innovation from Enovix.

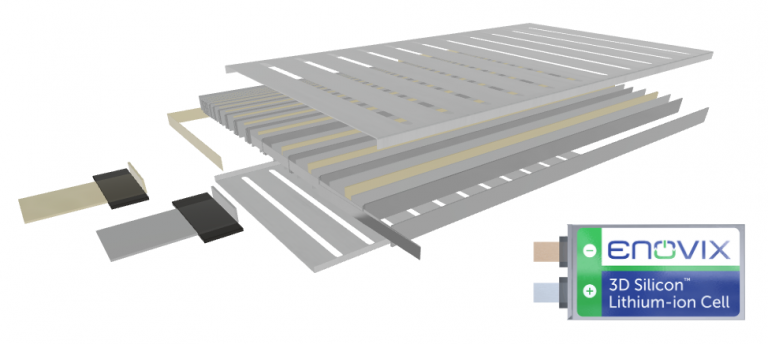

Enovix’s BrakeFlowTM technology is a system within the battery that prevents the dangerous thermal runaway that can occur if a Li-ion battery is pierced or severely damaged. Thermal runaway is the often-fiery chain reaction caused by the extremely quick discharge of a cell from a short, and this is obviously far from desirable in a wearable or handheld device. BrakeFlow is a safety mechanism that is enabled by Enovix’s 3D multiple parallel cell-to-busbar connection architecture. It sits at the busbar junction and includes a resistor with a set value. Under normal operation, the battery electrodes carry a small current, but in the event of an internal short caused by damage to the battery, the BrakeFlow system regulates the resulting current spike at the short area. This current regulation prevents said area from overheating, thus inhibiting thermal runaway. Enovix has tested this technology with fully charged cells to ensure it works more reliably than batteries tested using less stringent industry-standard testing methods.

It would not seem there are development boards per se for Enovix’s technology, but that does not mean that it cannot be evaluated or customised for a product-specific application.

(All images sourced from Enovix)