Products

Manufacturers

Applications

iC-Haus’ iC-PXL3212 presents a disruptive alternative to magnetic encoder technology, with much higher accuracy and less requirement for high-precision alignment between the sensor and a reference target. Key applications include:

- Lidar

- Robotics

- Medical equipment

- Industrial automation

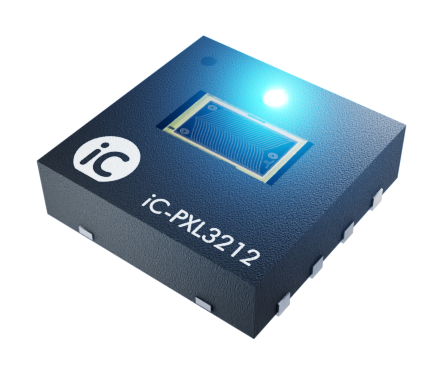

The iC-PXL3212 optical-reflective encoder iC incorporates both a blue LED light source, with power control, and an HD phased array photosensor with on-chip interpolation, eliminating the need for external alignment of separate electro-optical components. It is designed for use with reflective code discs a small as 10 mm in diameter and linear scales, though iC-Haus can assist customers in selecting code targets that deviate from normal requirements, such as for use in high-shock or high-vibration environments.

The iC-PXL3212 chip itself can also be customised after fabrication, thanks to iC-Haus’ OTP FlexCount technology, and does not require additional lenses for operation.

Available in an ODFN8-3×3 package, the iC-PXL3212 features 2x digital AB or sin/cos analogue outputs. The latter allows for external interpolation and resolution enhancement. The in-built signal amplifiers exhibit low-noise operation with high EMI tolerance, and the SoC is suitable for operation in environments ranging from -40°C to +125°C.

The picture above shows the scanner board for the iC-PXL3212, which is provided with a code disc as part of the full evaluation kit. A motherboard, also supplied by iC-Haus, enables you to change settings on the fly without having to rewrite code during testing.

If you have a commercial project and wish to test this technology, fill out the form below, and ipXchange will put you in touch with iC-Haus for consultation to select the right encoder solution for your application.

(Images sourced from iC-Haus)